Email

Email

[email protected]

Email

Email

There are many grades of stainless steel, So let us discuss different types of grades and families of stainless steel and you decide which one is best for your application

As the world is growing in various manufacturing sector the need of the steel is also increasing day by day therefore it is neccessary for us to understand the grades and families of stainless steel

The alloy of stainless steel is not single. As the stainless steel get its corrosion resistance from chromium there are many alloy combination by which stainless steel is manufactured. So it is very important for us to determine the best combination for our product

Now, lets us understand this

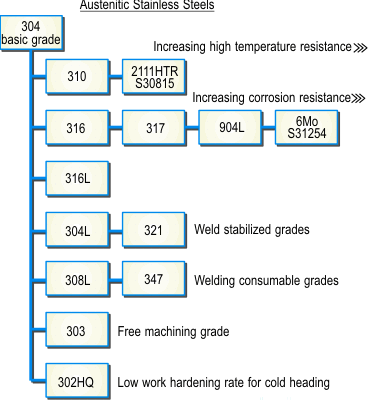

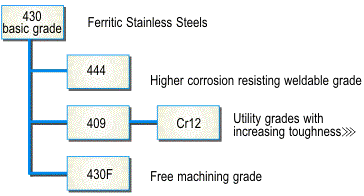

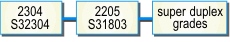

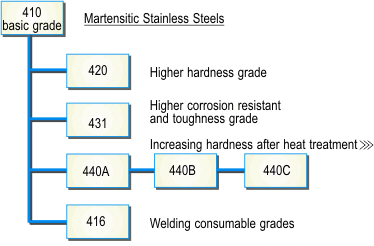

These are the families of stainless steel now let us look at the Grades As we have discussed about the families and within these families there are different grades which have specific properties such as magnetism, corrosion resistant, touchness and alloy composition

As there are many different grading system and standard of steel it become difficult for us to obtain the unique composition of a alloy For eg:

So when ever we are buying the steel we should specifiy the correct grade to the manufacturer because any difference in composition of stainless steel can have the performance problem In a working environment

For eg if you are ordering 304 stainless steel stainless steel then it must contain the following composition

Austeniic family is popular and most widely used It contain nickel and chromium while some grade also include molybdenum and manganese They have good corrosion resistance and provide good weldibility 303, 304, 316, 310 and 321 grades are Popular grades of austenitic stainless steel

Ferritic contain low nickel content which makes it cost effective. chromium, niobium and/or titanium and molybdenum are there to improve toughness and corrosion resistance.These are mostly used in kitchenware and many indoor applications. 409 and 430 grades are common grades of ferritic stainless

Many Duplex grade provide combined properties of ferritic stainless steel and austenitic steel. They have good resistance against chloride solution and provide good formability and weldability as compare to other steel families. Duplex Steel include are 318L,2205,2202, LDX 2101, LDX 2304, 2507 etc

| Grade | EN NO/UNS | Type | Approx Composition | ||||||

|---|---|---|---|---|---|---|---|---|---|

| r | NI | Mo | N | Mn | N | u | |||

| 2101 LOX | 1.41621 S32101 | Lean | 21.5 | 1.5 | 0.3 | 0.22 | 5 | ||

| DX2202 | 1.40621 S32202 | Lean | 3 | 2.5 | 0.3 | 0.2 | 1.5 | ||

| RDN 903 | 1.44821 S32001 | Lean | 20 | 1.8 | 0.2 | 0.11 | 4.2 | ||

| 2304 | 1.43621 S32304 | Lean | 23 | 4.8 | 0.3 | 0.10 | |||

| 2205 | 1.44621 S31803 S32205 | Standard | 22 | 5.7 | 3.1 | 0.17 | |||

| 2507 | 1.44101 S32750 | Super | 25 | 7 | 4 | 0.27 | " | ||

| ron 100 | 1.45011 S32760 | Super | 5 | 7 | 3.2 | 0.25 | 0.7 | 0.7 | |

| Ferrlnox 255/Uranus 2507Cu | 1.4507/ S32520 S32550 | Super | 5 | 6.5 | 3.5 | 0.25 | 1.5 | ||

It is popular in applications requiring a precise, hardened edge. Due to addition of carbon tempering and hardening is possible therefore it is used in medical tools, knives, razors and many more application Martensitic & Precipitation Hardening steel offer good corrosion resistance. 410 and 420 are the grades of martensitic and precipitation hardening steels

| Alloy Group | Austenitic | Duplex | Ferritic | Martensitic | Precipitation Hardening |

|---|---|---|---|---|---|

| Magnetic Response | Generally No | Yes | Yes | Yes | Yes |

| Work Hardening Rate | Very High | Medium | Medium | Medium | Medium |

| Corrosion Resistance | High | Very High | Medium | Medium | Medium |

| Hardenable | By Cold Work | No | No | Quench & Temper | Age Harden |

| Ductility | Very High | Medium | Medium | Low | Medium |

| High Temperature Resistance | Very High | Low | High | Low | Low |

| Low Temperature Resistance | Very High | Medium | Low | Low | Low |

| Weldability | Very High | High | Low | Low | High |